In our second deep-dive into the fire suit assembly, we peel back the “onion” past the outer shell to examine the design and function of the middle layer: the moisture barrier. In a complex piece of personal protective equipment (PPE) like the fire suit, certain essential elements don’t always get the attention they deserve. In our opinion, the moisture barrier is the fire suit’s unsung hero. Here’s why.

Not visible, but essential

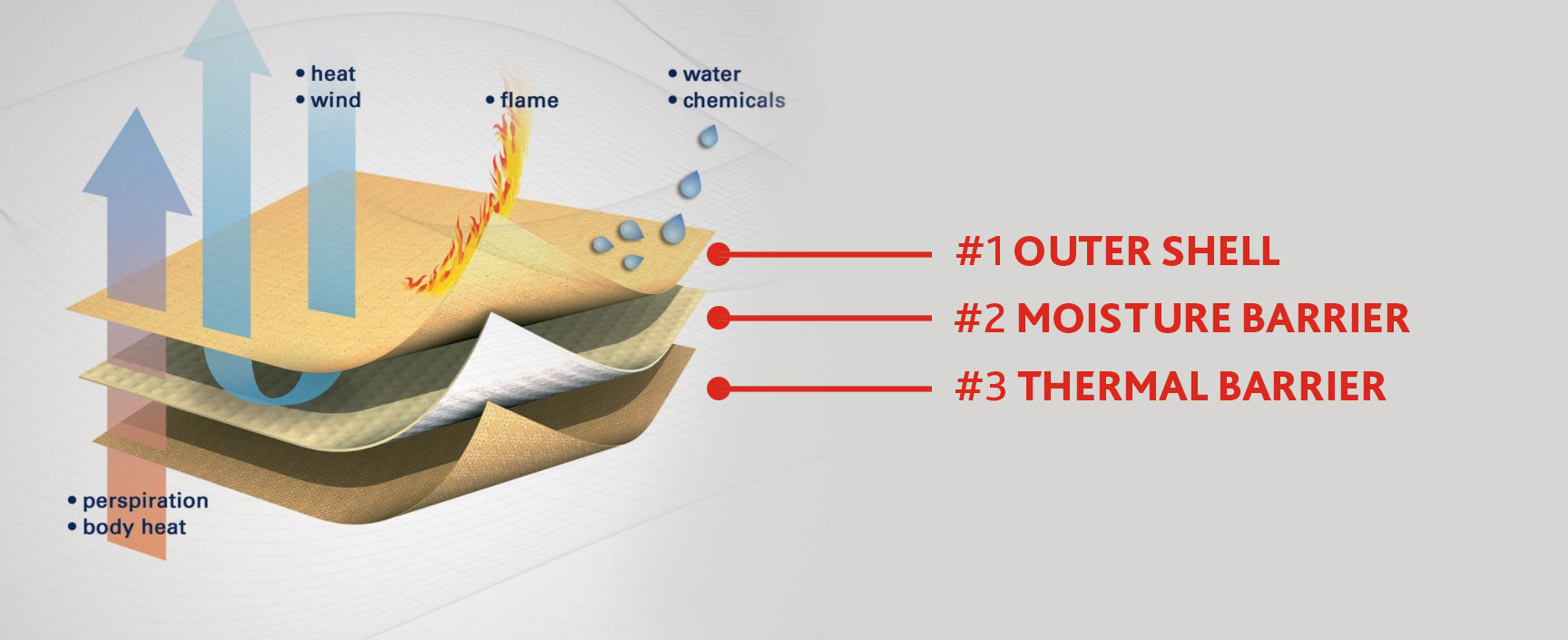

Sandwiched out of sight between the outer shell and the thermal barrier, the moisture barrier is often a neglected layer of the fire suit assembly. Firefighters interact with the outer shell and the thermal barrier when they don and doff their garments, but their comfort and safety are very dependent on the quality of the hidden moisture barrier. Responsible for thermal protection, breathability and waterproofness, the moisture barrier layer plays a crucial role in the integrity and structure of the fire suit.

What exactly is the moisture barrier?

The moisture barrier consists of a two-layered membrane: a porous polymer film and the flame resistant, non-woven fabric substrate it’s bonded to for support. The membrane film is typically composed of polyurethane, polyester, or ePTFE (expanded polytetrafluoroethylene).

Moisture management

The DWR-treated outer shell is designed to provide a first defense against water, but the moisture barrier takes it one step further. The membrane’s micropores are bigger than a molecule of steam, but smaller than a drop of water. This allows evaporated sweat to escape away from the body, without letting any fluids in (water, liquid chemicals, blood and potential blood-borne pathogens, etc). This unique mix of breathability and waterproofness is key, as moisture in the suit can increase the risk of steam burns or scalding in a hot environment.

Thermal protection

Not all membranes are equal. While polyurethane and polyester may appear to perform similarly, at least in terms of moisture management, they don’t provide thermal protection equal to that offered by ePTFE. Polyurethane and polyester begin to degrade around 150°C and melt at 170-180 °C. That may sound hot, until you consider that the outer shell and thermal barrier can withstand temperatures up to 350 °C. A fire suit is only as safe as its weakest layer, and it’s essential that the moisture barrier performs to the same level as the other layers.

That’s why TenCate Protective Fabrics recommends investing in a moisture barrier with a ePTFE membrane for your fire suits. It’s simply not worth taking a shortcut in the name of cost-effectiveness, when you consider the ultimate impact on your firefighters’ safety.

Don’t forget the seams

The membrane is too delicate to be stitched (which would pierce it and create holes allowing moisture in), so it’s taped at the seams. It’s crucial that the seam tape is composed of the same polymer as the rest of the membrane, in order to provide consistent thermal protection.

Inspection = protection

A fire suit may outwardly appear intact after an intervention, but that isn’t a guarantee that the moisture barrier membrane is still integral. It’s very important to properly inspect the moisture barrier often, to make sure it hasn’t melted and compromised the rest of the fire suit. An inspection opening is designed into fire suits, allowing laundries to unzip the garment from inside and pull the moisture barrier out for thorough examination. An inspection protocol is the best way to ensure the performance of your garments is protected.

Graphic of the multiple essential layers of a fire suit, each with different protective qualities.

Graphic of the multiple essential layers of a fire suit, each with different protective qualities.

Choosing the best fabric for your suits

The moisture barrier may be hidden from sight between the outer shell and the thermal barrier, but it shouldn’t be an afterthought. It plays a crucial role in managing moisture, reducing heat stress, keeping out chemicals and blood-borne pathogens, and providing thermal protection. The moisture barrier deserves to be selected and maintained with care as a crucial part of your fire suit assembly.

At TenCate Protective Fabrics, we understand the impact each individual layer has on the overall functionality and comfort of your firefighter suits. Curious to learn more about the latest in protective clothing for firefighters and other trends in this industry? Please reach out to one of our Fire Service Experts .

.png?width=1080&name=Peeling%20back%20the%20fire%20suit%20%E2%80%9Conion%E2%80%9D%2c%20layer%20%232%20the%20moisture%20barrier%20(1).png)

.png?width=399&name=Untitled%20design%20(50).png)