Protection against heat

The outer shell is the firefighter’s very first line of defense. It might seem like a no-brainer, but the fire suit wouldn’t be a fire suit without the guarantee of protecting its wearer from heat and flames in structural fire incidents. At TenCate Protective Fabrics, we use innovative fibers to provide superior thermal protection.

Protection against water

It’s obvious that the outer shell must be fire-retardant, but equally crucial is the protection it offers from moisture. The threat of water is threefold, since the risks of increased garment weight, chill factor, and steam burns all increase when a fire suit gets wet.

As firefighters often carry out physically demanding, non-fire related work activities out in the elements, it’s crucial that their garments are DWR (durable water-repellent) treated. A wet garment is a heavy garment, so the DWR finish is there to prevent the fabric from absorbing water and burdening the firefighter with extra weight. When a suit gets wet, the chill factor is also affected, making the firefighter feel colder. Finally, water repellency is essential because moisture can quickly reach boiling point in a hot environment, raising a firefighter’s chances of getting scalded inside their suit.

High visibility

In this case looks do matter, as it’s ultimately the outer shell’s responsibility to provide differentiation on the scene at emergency interventions. A colorway like red, for instance, can help firefighters to easily identify their colleagues from other emergency personnel such as police or ambulance workers, while helping bystanders clearly spot the firefighters from a distance. The outer shell also may include retro-reflective striping to help firefighters stand out in situations of low visibility. Every glimpse of light gets reflected off the striping back to the source.

Durability

“The stronger the better” isn’t always the case, especially when it comes to safety considerations. The outer shell must be tough enough to provide protection against abrasions, cuts, and lacerations on the job, without being so unyielding that a firefighter can’t tear the suit to escape in the event they become pinned down during an intervention. On top of these safety requirements, the fabric’s looks and protective functionality must stand up to frequent washing, as looking good and staying well-protected should go hand in hand.

The strength, durability, and performance of the outer layer’s fabric is determined both by its composition (the fiber blend) and its construction and weight. Finding exactly the right balance between all three was a product design challenge we recently took on at TenCate Protective Fabrics while developing an innovative outer shell fabric.

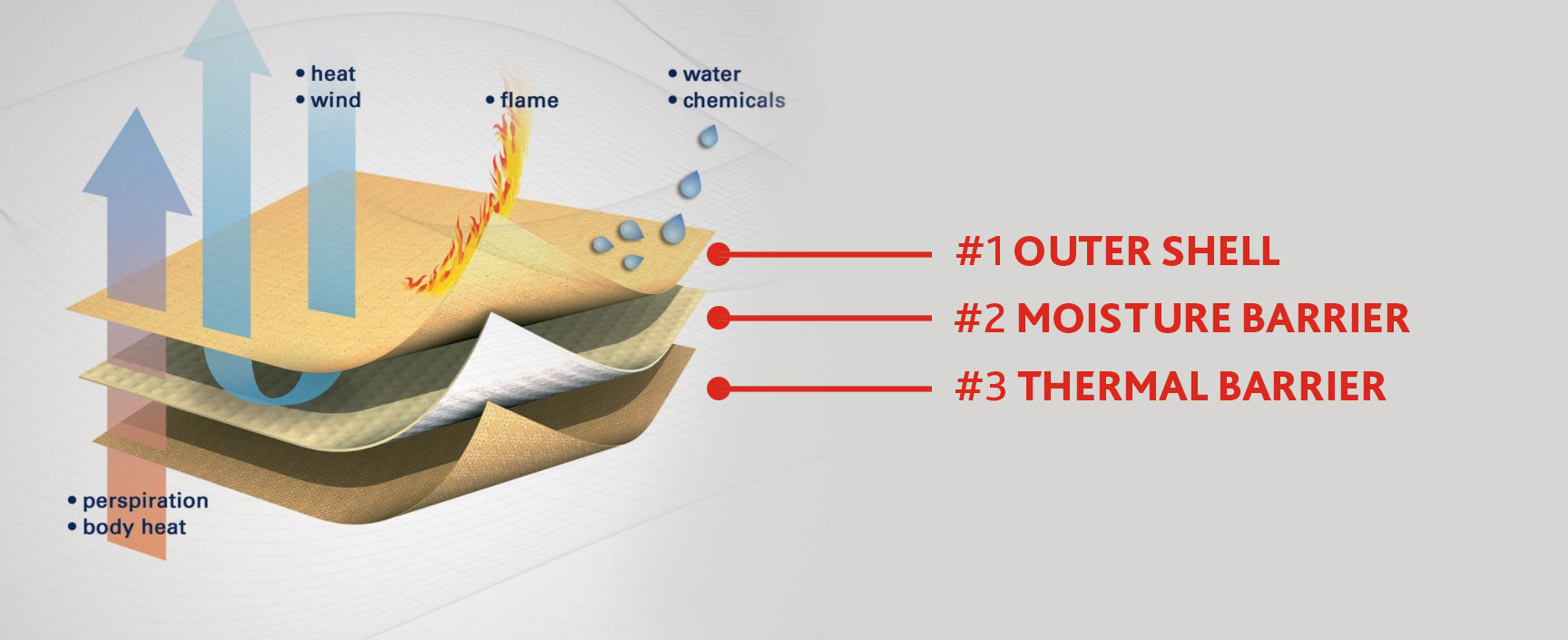

Graphic of the multiple essential layers of a fire suit, each with different protective qualities.

Graphic of the multiple essential layers of a fire suit, each with different protective qualities.

Choosing the best fabric for your suits

The outer shell may be the hardest-working layer of the fire suit, but it doesn’t need to be heavy and cumbersome. Thanks to the latest technology, it’s possible to choose a lightweight fabric that reduces heat stress and discomfort, while still providing excellent thermal protection.

At TenCate Protective Fabrics, we understand the impact each individual layer has on the overall functionality and comfort of your firefighter suits. Curious to learn more about the latest in protective clothing for firefighters and other trends in this industry? Please reach out to one of our Fire Service Experts.

.png?width=399&name=Untitled%20design%20(50).png)