We know that as a health and safety manager, your employees’ safety and comfort are your priority. But did you know there are workwear fiber options out there that meet your requirements for safety and comfort, and are kinder to the environment?

As the industry continues to evolve, the future of workwear is looking greener, with no compromises on safety. You can be a part of that future today when you choose the most sustainable fibers available on the market.

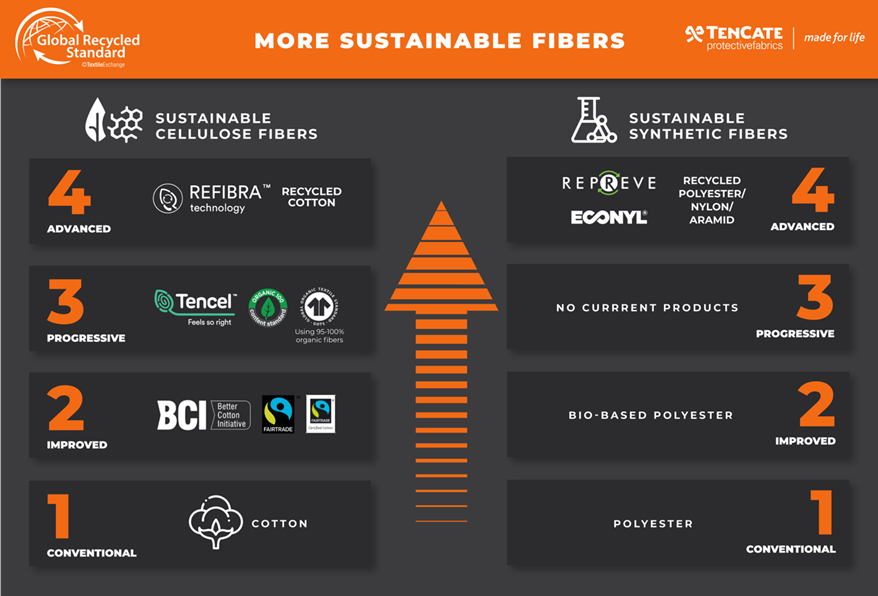

At TenCate Protective Fabrics, we have broken down the most used sustainable fibers for workwear into four levels. These levels are determined by a series of benchmarks, such as the Higg Index, Textile Exchange, and Made-by®, which measure typical sources of sustainable fibers.

From least sustainable to most sustainable, the levels are:

- Conventional

- Improved

- Progressive

- Advanced

Let’s look at the sustainable fibers currently on the market and how they measure up accordingly.

Sustainable Cellulosic Fibers

- Advanced: Recycled Cotton or Cellulosic

- Optimum circularity

- Often blended with virgin improved or progressive fibers

- Example: REFIBRA technology from Lenzing™ upcycles cotton scraps from garment production - Progressive: Bio-Cotton or TENCEL™Lyocell

- Cultivated without synthetic pesticides or chemical fertilizers

- Requires less water consumption

- Third-party certification standards (e.g., GOTS) assure organic product claims

- Example: TENCEL™ Lyocell is made from wood pulp, requiring less water, no pesticides or fertilizers, and is more comfortable to wearers - Improved: like BCI-cotton or Fairtrade cotton

- Better Cotton Initiative (BCI) promotes better programs for global cotton production, taking social and environmental aspects into account

- Fairtrade creates new opportunities for economically disadvantaged farmers in third-world countries - Conventional: Cotton

- One of the most commonly used low-cost fibers

- Requires lots of water and pesticides that can be environmentally detrimental

Sustainable Synthetic Fibers

- Advanced: Recycled

- Well-known options include recycled polyester (Repreve®) and recycled nylon (Econyl®)

- Smaller greenhouse gas emissions

- Uses less water and energy

- No non-renewable resources used

- Recycled aramids already used in non-workwear settings (non-wovens), but we expect to see initiatives in protective clothing

- Example: Repreve® is made from post-consumer PET bottles - Improved: Bio-Based

- Developed from renewable and bio-based feedstocks like sugarcane and corn

- Better supply chain

- Many conventional fibers enter the market with a portion of bio-based content - Conventional: Virgin

- Polyester and nylon are common and popular

- Energy-intensive manufacturing

- Requires large amounts of fossil fuels to produce

- Examples: modacrylics and aramids

Investment and Return

Many companies are making small steps toward sustainability, such as swapping conventional solutions for improved options, but to truly reduce our ecological footprint, we must go further. This will require greater upfront investment, but it will result in an even greater return.

Our research has found that progressive and advanced category fibers consistently perform well.

- Example: TENCEL™ Lyocell

Increased comfort

High mechanical properties

Excellent color retention

Paying a premium price for a higher quality product pays off in the long term: your product remains wearable and workable for longer, giving you the best return for your money.

Ask for the Life Cycle Analysis (LCA) data reported in an EPD®, an environmental product declaration. This gives you a clear picture of the lifecycle environmental impact of a product and lets you know how hard your protective garments are working for you.

While sustainable innovations in workwear are common, they're less so in the FR (flame-resistant) market. At TenCate Protective Fabrics, we have worked hard to develop sustainable solutions in this space. We’re delighted to share that we recently launched the first-ever sustainable FR-treated fabric—a significant step forward of which we are very proud.

.png?width=399&name=Untitled%20design%20(50).png)