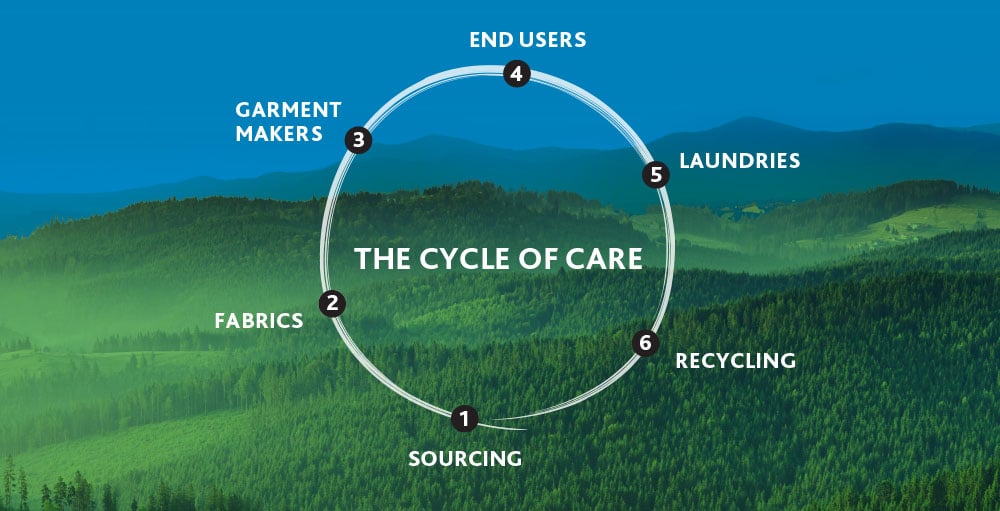

The textile industry is one of the major polluting industries in the world. As members of that industry, it is our responsibility to be a part of the solution in working to reduce our ecological and social impacts. But it’s not just materials manufacturers like ourselves who should consider how to move our industry towards greater sustainability: each stakeholder along the value chain plays a role in contributing towards our collective success. To illustrate our joint responsibility in finding sustainable solutions for protective workwear, we developed the Cycle of Care:

From sourcing to recycling

The cycle of care follows the lifecycle of protective workwear products, from sourcing raw materials to recycling product, with stops along the way at which each party in the process can consider how they might contribute to collective sustainability goals.

- Sourcing

At TenCate Protective Fabrics, we use recycled polyester, which consumes less energy to produce, and lyocell, which requires less water use. Learn more about recycled polyester here and lyocell here. - Fabric Selection

When you opt for a high-performing sustainable fabric, you can get the best of all the worlds: great moisture management, touchable softness, enhanced comfort, and excellent durability and colorfastness. For example, recycled polyester retains both color and mechanical performance extremely well. - Garments

Garment manufacturers can maximize a garment’s sustainability factor by being economical with material usage, selecting sustainable yarns, zippers, and striping, and minimizing their use of plastic in packaging. Plus, constructing higher-quality garments that can stay in service for longer reduces waste and the rate of consumption. - End User

There are a multitude of ways end users can play their part in moving our industry toward a more sustainable future. Proper garment wear and maintenance, creating and striving toward overall corporate sustainability goals, and choosing the most sustainable options available for their workwear are just a few. - Laundries

Industrial laundries are responsible for keeping protective workwear maintained and in rotation for a product’s lifecycle, and their washing and drying process can have quite the environmental impact. To help laundries lessen their impact, fabric suppliers can develop sustainable fabrics that are designed for energy-efficient laundering. - Recycling

At the end of one product’s lifecycle, a new product’s can begin: workwear fabrics can be made more sustainable when they are made with recycled fibers such as recycled polyester in place of virgin fibers. Using a smaller proportion of or no virgin fibers reduces energy consumption and chemical fertilizer usage, improves social impacts, and shrinks carbon footprints.

It's all well and good for anyone along the Cycle of Care to claim they’re offering a more sustainable product, but how can you know for sure? Transparency is key to creating long-lasting sustainable solutions, so when in doubt, ask for the Environmental Product Declaration.

Regulating transparency & building trust

An Environmental Product Declaration, or EPD®, is a type III declaration compliant with ISO 14025 that provides relevant, verified, and comparable information about the lifecycle environmental impact of products. As our partners in the workwear value chain aim for high-quality, comfortable workwear with the smallest environmental footprint possible, EPDs® are an invaluable tool in holding us all accountable to our rising standards.

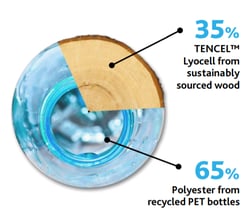

At TenCate Protective Fabrics, we provide an EPD® for Tecawork® Ecogreen, Tecasafe® Ecogreen, Tecapro® Ecogreen, three product families in our Ecogreen portfolio, which was born out of our desire to develop products with sustainability in mind from the ground up. These fabrics are made with mechanically recycled polyester fibers made of PET bottles mixed with lyocell fibers made with sustainably sourced wood.

We are proud to offer more sustainable protective workwear fabrics to our partners in the Cycle of Care and play our part as fabric suppliers in reducing our industry’s environmental impact. In fact, developing long-lasting sustainable solutions is part of our mission. We strive to be transparent and valuable partners to end users, garment manufacturers, and industrial laundries. Working together as an industry, we can multiply our efforts to make a greater and more positive impact on the planet we all call home.

.png?width=1080&name=The%20Cycle%20of%20Care%20(2).png)

.png?width=399&name=Untitled%20design%20(50).png)

.png?width=399&name=Untitled%20design%20(37).png)